Module Project

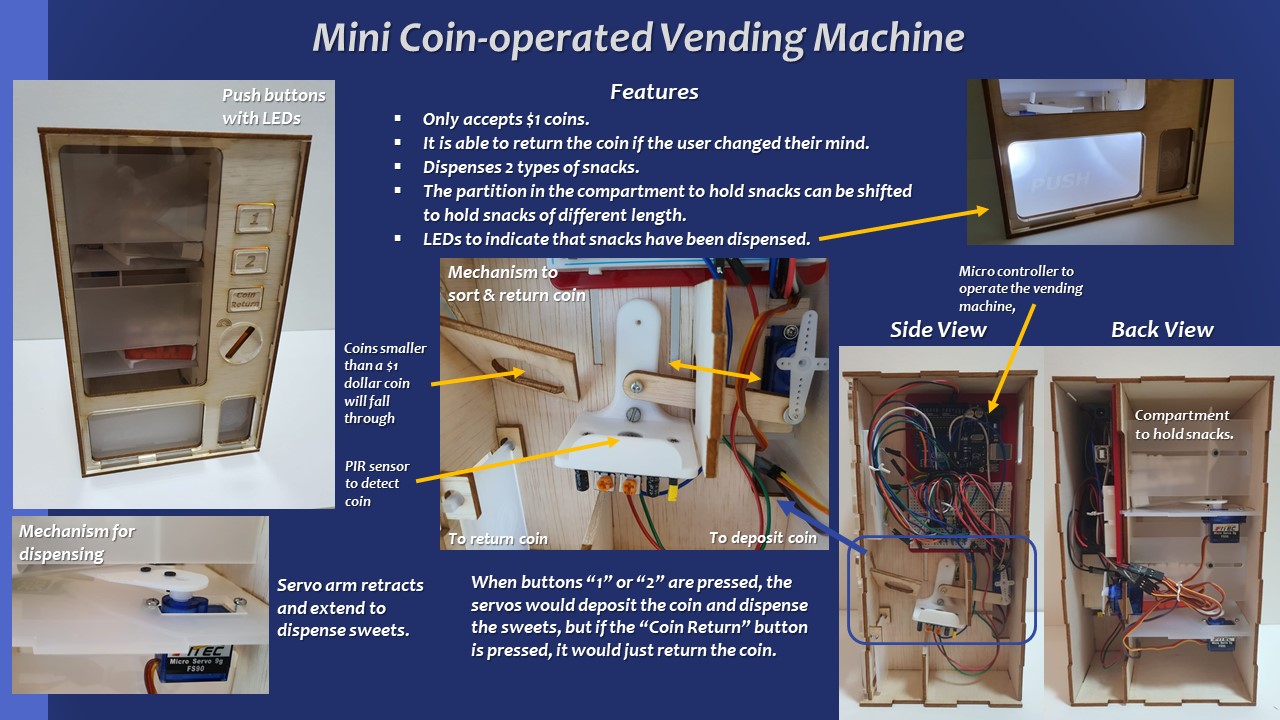

Mini Coin Operated Snack Machine

Description

It dispenses snacks(sweets), using a gravity feed magazine, whenever a coin is inserted. After inserting a $1 coin, the user can select between two options through the push buttons. Servos are used to dispense the snack and return the coin.Fabrication techniques

| Technique | Makes |

|---|---|

| Laser Cutting | Casing and Dividers |

| 3D Printing | Dispensing Mechanism |

| CAD Design | Hardware design and patterns for engraving |

| Processing System | Arduino Uno or compatable CPU |

| Input Devices | Push Buttons, PIR Sensor |

| Output Devices | Servos, LEDs |

| Power | Single 5V DC plug |

Bill of Materials

| No. | Quantity | Description | Cost (each) |

|---|---|---|---|

| 1. | 1 | Arduino Uno or compatable CPU | $6.50 |

| 2. | 3 | Mini Servo | $2.45 |

| 3. | 3 | 2-Pin Mini Pushbuttons | $0.06 |

| 4. | 5 | LEDs, white x2, yellow x3 | - |

| 5. | 1 | PIR Sensor | $1.50 |

| 6. | 1 | A2 3.5 mm Ply Wood | - |

| 7. | 1 | A3 3 mm Clear Acrylic | - |

Computer Aided Design (CAD)

I started of by creating the base followed by the other sides of the housing, i also created slots for the shelfs and partitions.

After creating an offset plane and sketch,i projected(Create > Project/Include ) the outline and slots from the left and right profile to create the divider.Then i created the back panel.

Next, i designed the front panel which consist of 2 pieces, the first piece is made of wood while the second piece is made of acrylic. I designed openings for the buttons, window, coins and push door.

I made a hole which acts as a hinge for the push door, after that, i designed the push door for the 2 compartments.

I then design the shelfs for the vending machine, i included openings and holes to mount the servo that is used for dispensing.

After that i created more dividers, to seperate compartments and also to hold the snacks.

I made a slope which sorts out $1 from the rest of the coins. The hole i made is slightly smaller than a new $1 coin.

Next i designed a mechanism to return and deposit the coin, i also designed a slot to mount the servo.

I designed a linkage to link the servo to that mechanism and also a housing to house the push buttons and LEDs.

Lastly, i designed an attachment for the servo to push and dispense the snacks. I also designed a movable partition so that i am able to fit snacks of different length.

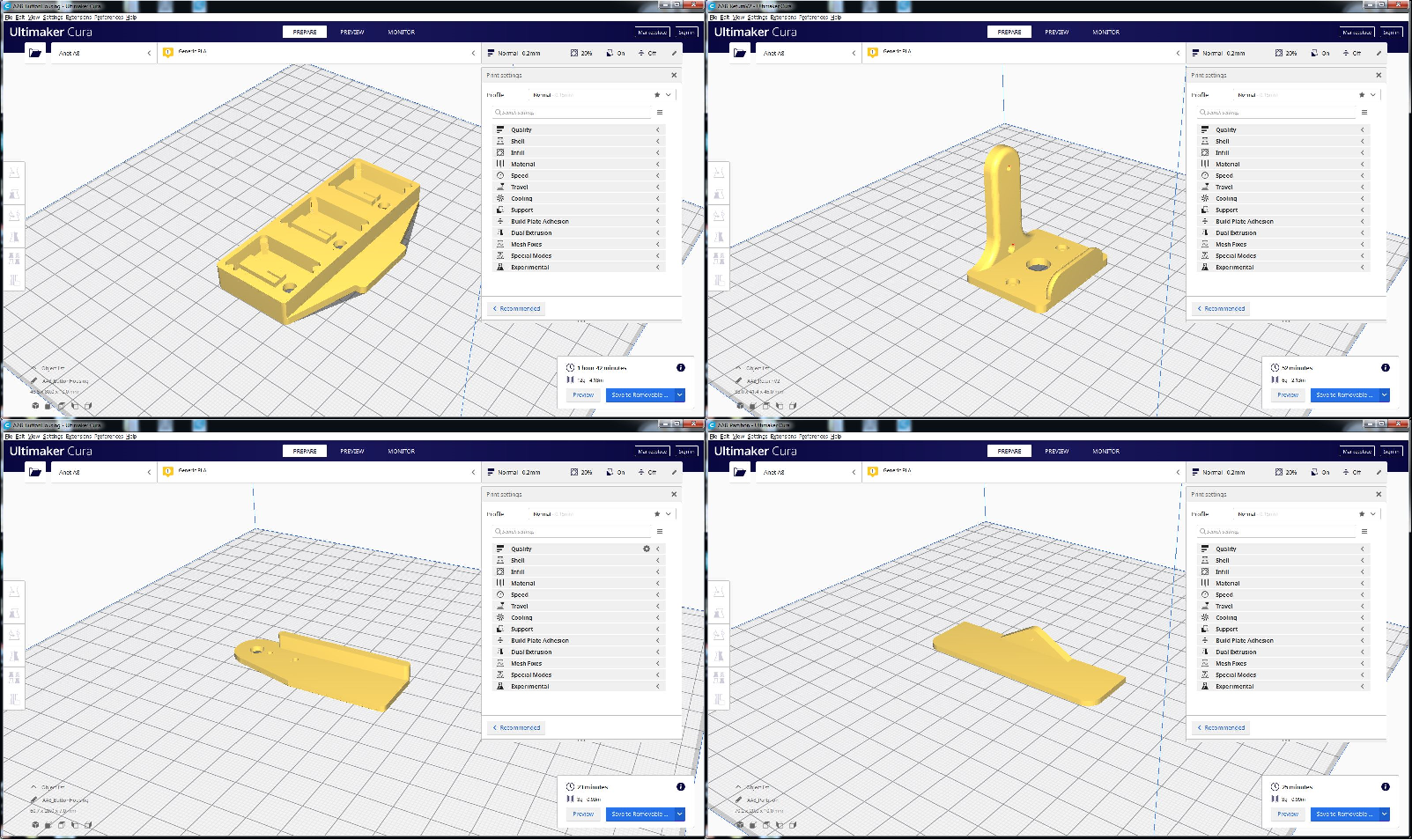

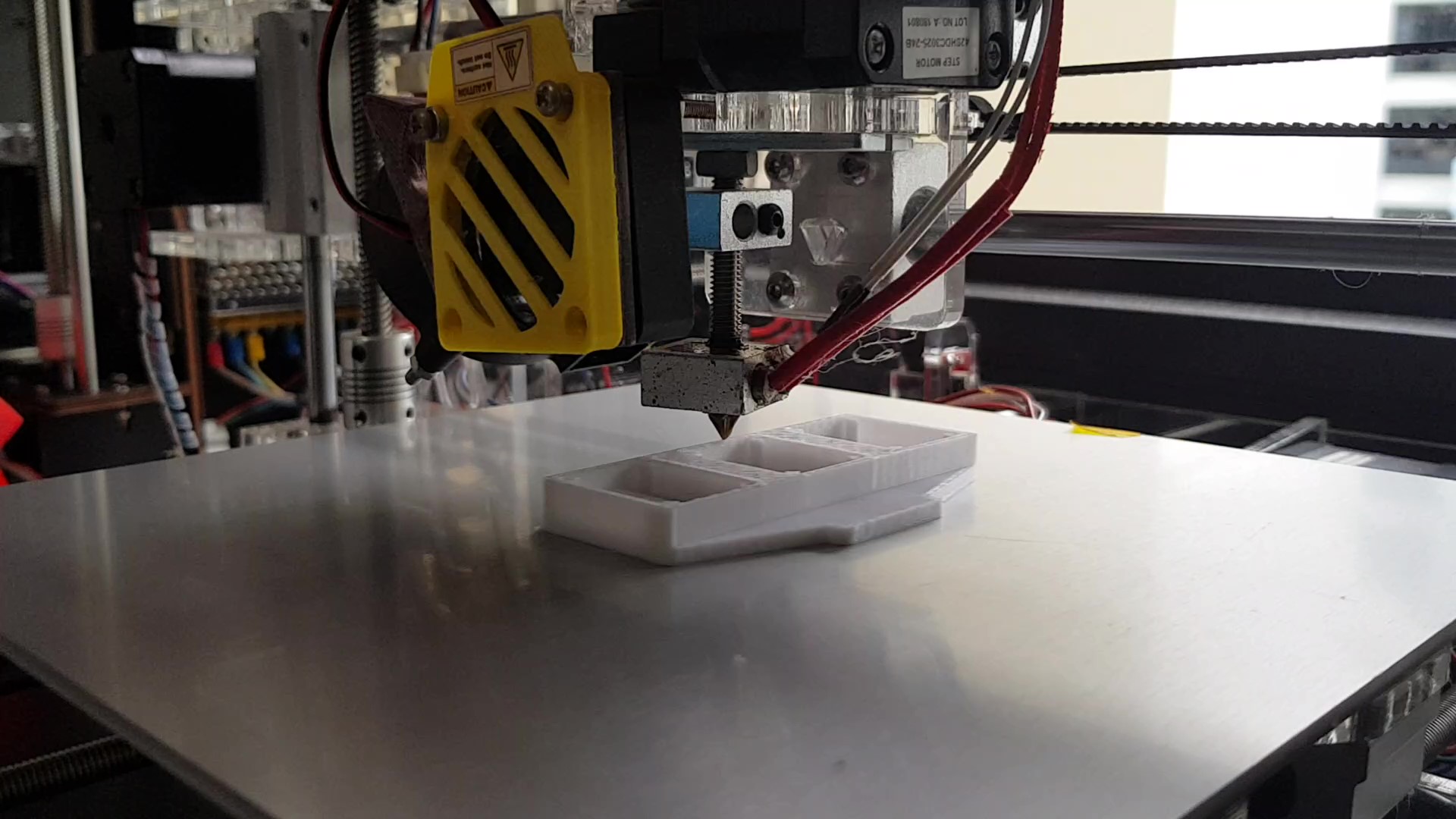

3D Printing

Go to Tools > Make > 3D Print and select the parts to be printed. Save it as Stl.

Open the stl file in Cura, change the settings and slice it.

Slicing Parameters

- Material : PLA

- Nozzle : 0.4mm

- Layer Height : 0.2mm

- Wall Thickness : 1.0mm

- Wall Line Count : 3

- Top Layers : 3

- Bottom Laters : 3

- Infill Density : 15%

- Print Speed : 50 mm/s

- Enable Retaction : Selected

- Generate Support : Not Selected

- Build Plate Adhesion Type : Skirt

3D Printed parts

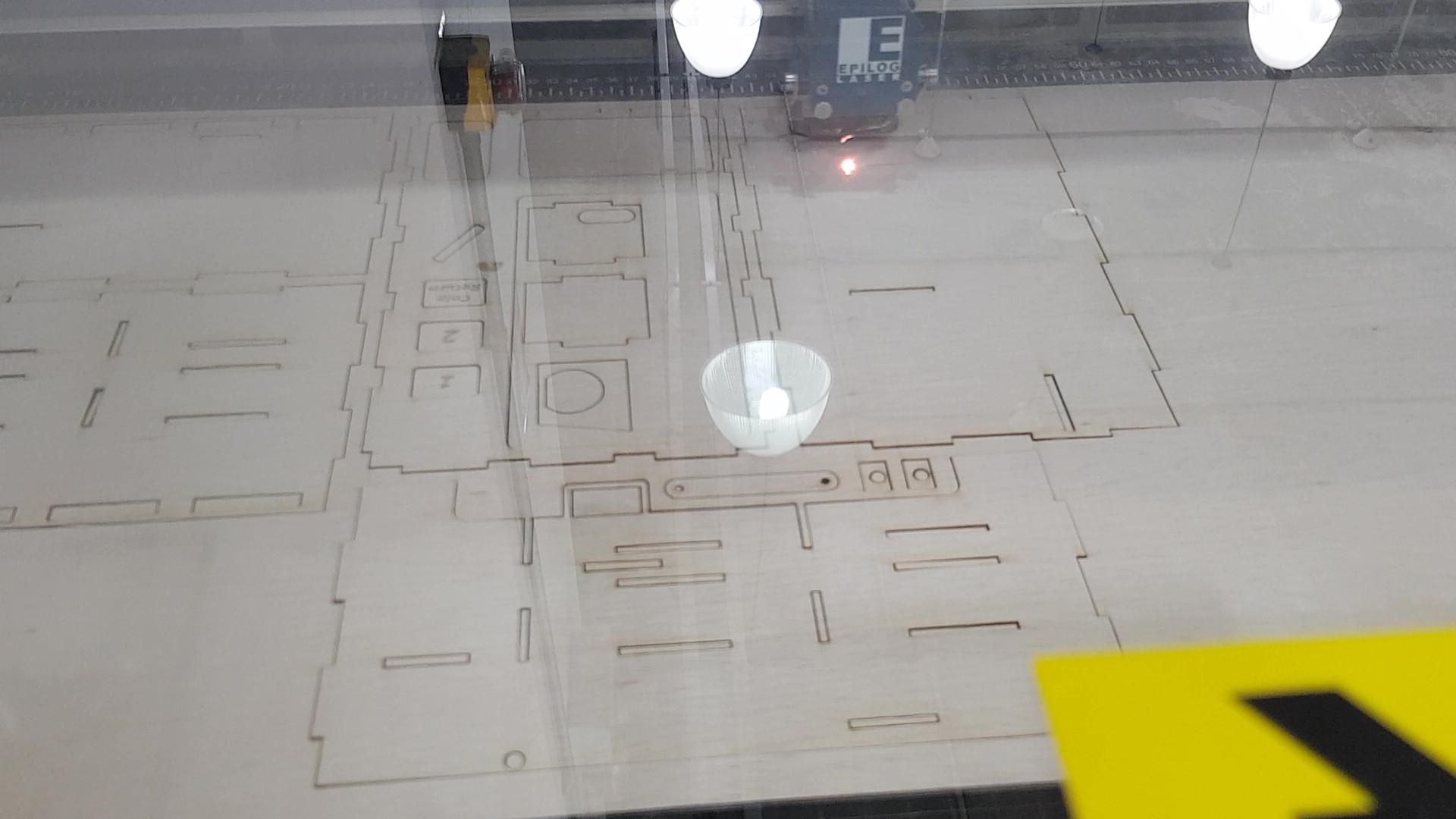

Laser Cutting

After finishing the design, i created a new sketch on each profile and save it as DXF.

Open inkscape and go to File > Import to insert the DXF file. The canvas size can be changed at File > Document Properties.

Parts

Programming

Testing of dispensing mechanism and program.

Assembly

Firstly, assembled the front, base and divider, the pieces are a bit loose, therefore i added glue.

I assembled the coin return mechanism and realised that the slope angle is not enough for the coin to slide.

To solve that issue, i changed the position of the linkage, it have lesser mechanical advantage, but the servo to strong enough.

I glued the rest of the parts and used rubber bands to hold it tight.

Next, I assembled the dispensing mechanism and partitions.

At first i wanted to use an arduino nano board, but i realised that there is enough space to fit the bigger uno board.

I replaced the screws with a longer one and mounted it onto the divider together with the breadboard.

After that, i connected the wiring the same way and also organised the wires with cable ties.

Lastly, using a pen knife, i cut a hole on the back plate for the USB cable and 5V power supply. I also 3D printed a part to cover the edges to make it look nicer.